INFA AIR: Propellers

A

new range of up-to-date and innovative propeller hubs; the speed at

which our aircrafts develop requires, in fact, a fast and regular

updating of the accessories and of those in particular that

influence the aerodynamic efficiency of your aircraft.

A

new range of up-to-date and innovative propeller hubs; the speed at

which our aircrafts develop requires, in fact, a fast and regular

updating of the accessories and of those in particular that

influence the aerodynamic efficiency of your aircraft. Mounting a variable pitch blade doesn't mean simply gaining speed; it also enables to handle the flight differently offering greater comfort, higher speed and especially savings thanks to the better use of power which reduces consumption of 20/30% on average besides the fact of using the engine in the best conditions and reducing its wear.

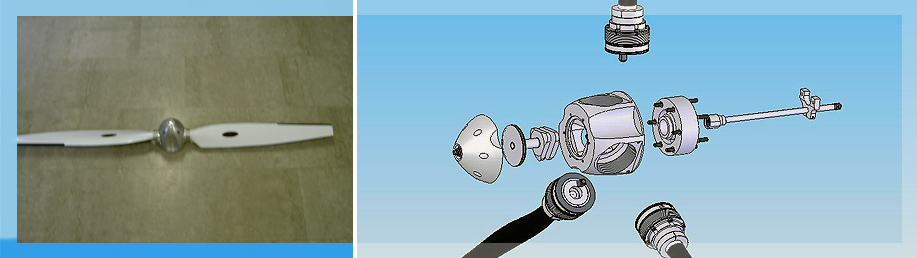

This

new series has been designed following a spirit of innovation and

its dimensions have been programmed so as to resist to any strain it

were to support during its proper utilization: the propeller hubs

are in fact definitely one of the largest on the market and their

diameter measures well 65 mm. The thrusts system has been

consequently increased, even though, thanks to mechanical craftiness,

one has managed to keep the outside dimension and weights within the

usual standards.

This

new series has been designed following a spirit of innovation and

its dimensions have been programmed so as to resist to any strain it

were to support during its proper utilization: the propeller hubs

are in fact definitely one of the largest on the market and their

diameter measures well 65 mm. The thrusts system has been

consequently increased, even though, thanks to mechanical craftiness,

one has managed to keep the outside dimension and weights within the

usual standards. Action has been taken also on the hydraulic system where it has been positioned in front of the propeller, as the case on the general aviation propellers, so as to reduce the moments of torsion originating from the masses distant from the rotation centre and enable an aerodynamic junction which appears as a metallic spinner and that can be mounted on planes with the right type of nose cones.

Why

has the hydraulic activation solution been chosen?:

Why

has the hydraulic activation solution been chosen?: The answer is very simple: the reliability of this system is at present unmatched and this has been proved by the general aviation where it is used on nearly all its aircrafts, given that it does not fear humidity and guarantees in case of failure return to the low pitch while continuing to fly even if with lower performances.

The electric system which is usually more delicate and exposed to humidity on this kind of propeller, or does not exist (see hydraulic/manual command and/or through oil governor) or, when the activation is electric, is positioned in such a way that it does not fear bad weather, while keeping in mind nevertheless that the dedicated electric engines do not undergo rotation and consequently do not suffer centrifugal force effects.

For this product we can be certain of having looked at safety and reliability before anything else.

TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICSCommand system:

OLEODYNAMIC

Fluid command's transmission:

through appropriate rotating joint easy to install (see picture).

Command:

MANUAL, with HYDRAULIC GOVERNOR (identical to those of the general aviation or ELECTRIC possibly subject to an electronic GOVERNOR.

Hubs and thrust bearings:

D. 65 mm.

Blades:

POWERFIN as the standard, all compatible ones when requested, supplied even by the customer.

Galleria Immagini

INFA.AIR s.r.l. © 2010 Copyright - All rights reserved -

Privacy Policy - P.IVA 10729790153

Realized by

Realized by